+86 13868429846

+86 13868429846 Top China AC Contactor Manufacturers | Quality Magnetic Contactors & Factories

When it comes to reliable AC and magnetic contactors, quality and performance are essential. Zhejiang Shuorui Electric Co., Ltd. stands out among top manufacturers in China, offering products engineered for demanding industrial applications. Their commitment to safety, efficiency, and innovation ensures consistent operation and durability, making their contactors suitable for both large-scale manufacturing and smaller setups. I have found their magnetic contactors particularly effective, enabling easy integration into existing systems. For enhanced operational efficiency and top-tier performance in your projects, consider selecting Zhejiang Shuorui Electric Co., Ltd. as your supplier.

Smart Ways To Ac Contactor Magnetic Contactor From Concept to Delivery Products

When it comes to selecting a magnetic contactor, global procurement professionals seek efficiency from concept to delivery. Understanding the intricacies of the manufacturing process is key to ensuring that you acquire high-quality products that meet your project's specifications. A magnetic contactor is essential for controlling high voltage power loads, and the design stage is crucial. It involves not just technical specifications but also an understanding of the application environment, such as temperature extremes and load variations. Engaging with manufacturers early in the concept phase can lead to tailored solutions that enhance performance and reliability. Once the design is finalized, the manufacturing process must be streamlined to ensure timely delivery. Choosing a supplier who incorporates lean manufacturing principles can significantly reduce lead times, thereby improving your supply chain efficiency. Additionally, leveraging advanced technology throughout the production phase ensures that each magnetic contactor is rigorously tested for quality standards and performance metrics. This is essential not only for compliance with international standards but also for ensuring that your operations run smoothly. Lastly, effective communication throughout the supply chain cannot be overstated. Partners who are transparent about production timelines, quality checks, and shipping logistics will ultimately help you mitigate risks and manage expectations. By adopting these smart strategies, you can secure reliable magnetic contactors that support your operational success and meet global market demands effectively.

Smart Ways To Ac Contactor Magnetic Contactor From Concept to Delivery Products

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| High Efficiency | Designed for optimal performance with minimal energy loss. | Reduced operational costs and enhanced system performance. | Industrial automation, HVAC systems. |

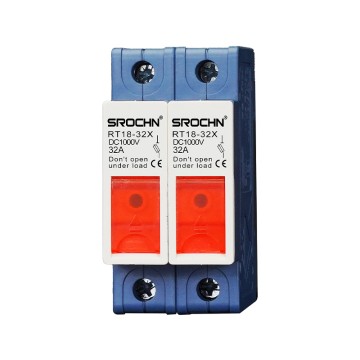

| Compact Design | Small form factor that saves space in control panels. | Easier integration into existing systems. | Power distribution, machine control. |

| Durability | Robust construction to withstand harsh environments. | Longer lifespan and reduced replacement costs. | Manufacturing plants, outdoor applications. |

| Safety Features | Includes overload protection and emergency stop options. | Enhanced safety for operators and equipment. | Construction sites, heavy machinery. |

| User-Friendly Interface | Intuitive controls for easy operation and setup. | Reduced training time and user error. | Control panels, automation stations. |

Quick Tips To Ac Contactor Magnetic Contactor Service Is The Best

M

Megan Turner

I am very pleased with this purchase! The quality is remarkable, as is the support service.

20 June 2025

A

Amy Parker

Very satisfied with my purchase. High-quality construction and very professional customer support.

04 June 2025

C

Chloe Rivera

What an amazing product! The quality is outstanding, and the service provided was superb.

09 June 2025

R

Ruby Martinez

Exceptional craftsmanship and quality! The customer service I received was nothing short of excellent.

09 June 2025

N

Naomi Baker

Very satisfied with the quality. The customer service team was very professional and attentive.

02 June 2025

L

Lily Ramirez

Very happy with this purchase! The quality is great, and the support was top-tier.

09 June 2025