+86 13868429846

+86 13868429846

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

Choosing the right Open Contactor is crucial for electrical systems. Experts emphasize that the selection process can be daunting. John Smith, an industry professional, states, “The right Open Contactor can make or break your project.”

Many factors play a role in this choice. Consider voltage ratings, current capacity, and coil design. Each component influences performance and durability. A mismatch could lead to inefficiencies or failures. Electrical systems require precision. Even small errors can cause major issues.

An Open Contactor should meet specific needs. Evaluate the environment where it will be used. Will it face extreme temperatures or vibrations? Remember, not all products fit every situation. There are various options available. Make choices based on detailed research and expert advice. Reflecting on past mistakes is essential for improvement.

Understanding open contactors is crucial for choosing the right one for your electrical needs. These components serve as switches in electrical circuits, controlling power to various devices. According to industry reports, open contactors account for approximately 15% of electrical control systems worldwide. Their reliability and efficiency make them essential in both residential and industrial applications.

In industrial settings, they are often used for motor control, heating systems, and lighting setups. When selecting an open contactor, factors like voltage rating, current capacity, and coil type are vital. A mismatch can lead to equipment failure or safety hazards. Many users overlook these details, leading to significant operational challenges.

Additionally, environmental conditions can affect performance. For example, contactors in dusty or humid areas may require special features to ensure longevity. Neglecting this aspect can result in frequent replacements and downtime. Reports suggest that proper selection can enhance system efficiency by up to 20%. However, many still struggle with understanding specifications and standards. This highlights the need for better training and resources in the industry.

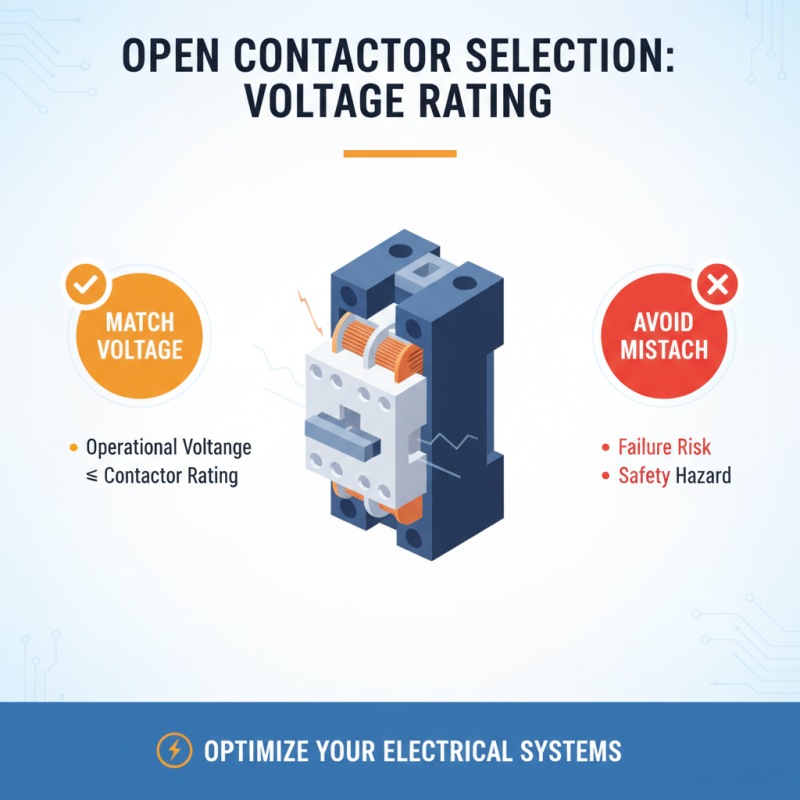

Choosing the right open contactor can greatly affect your electrical systems. One crucial factor is the voltage rating. Ensure the contactor can handle the operational voltage in your circuit. A mismatch here could lead to failures or safety hazards.

Another important consideration is the current rating. Look for a contactor that matches or exceeds your load requirements. Oversizing can be wasteful, while undersizing might cause overheating. Pay attention to the environmental conditions as well. Some contactors are better suited for high humidity, dust, or extreme temperatures.

Lastly, think about the control voltage. DC and AC systems have different needs. Ensure the contactor is compatible with your control system. Balancing these factors can be tricky, and you may find yourself second-guessing choices. The right contactor should fit your needs without overcomplicating your setup.

When choosing an open contactor, it's crucial to evaluate electrical specifications. The voltage rating is vital. It determines the maximum voltage the contactor can handle. If this rating is too low, it could lead to failures. Always check the compatibility with your electrical system.

Current rating is another critical aspect. This rating indicates how much current the contactor can manage without overheating. A common mistake is selecting a contactor without considering the load. It’s essential to calculate your system’s needs accurately. Ideally, you should choose a contactor with a rating higher than your requirements. This creates a safety margin.

Additionally, the coil voltage should match the control signal. Mismatches can cause erratic operation. Take time to evaluate the environment as well. Conditions such as humidity and temperature impact performance. Look for features like surge protection or extra insulation. Reflect on these elements to find what suits your specific application best.

| Specification | Value | Description |

|---|---|---|

| Voltage Rating | 120/240 V | Nominal voltage the contactor can handle. |

| Current Rating | 30 A | Maximum current the contactor can support without overheating. |

| Number of Poles | 3 | Number of contacts used to control circuits. |

| Coil Voltage | 24 VDC | Voltage required to energize the contactor coil. |

| Operating Temperature | -10 to 50 °C | Temperature range within which the contactor operates safely. |

| Insulation Class | Class F | Indicates the thermal endurance of the materials used in the contactor. |

| Mounting Type | DIN Rail | Type of mounting for easy installation in electrical panels. |

| Certification | UL listed | Indicates compliance with safety standards. |

When selecting an open contactor, understanding the various types is crucial. Open contactors can vary widely in specifications and functionality. The two most common types are electromagnetic contactors and solid-state contactors. According to industry reports, around 60% of applications use electromagnetic types due to their reliability and broad compatibility with different systems. Solid-state contactors, while faster and more efficient in certain scenarios, find their niche mainly in high-speed operational needs.

Tip: Always evaluate the specific voltage and current ratings required by your application. Matching these parameters is essential for optimal performance. Failure to do so could lead to equipment damage and increased operational costs.

Different environments demand different solutions. Industrial settings often require contactors rated for high thermal loads, whereas residential setups might need less robust options. In some instances, users overlook environmental factors, which can lead to premature failures. The longevity of contactors relies heavily on their installation conditions.

Tip: Regularly inspect contactors for wear and tear. This practice can prevent unexpected outages and costly repairs. Sometimes, users assume their existing models will continue to perform without checks, which can be a critical oversight.

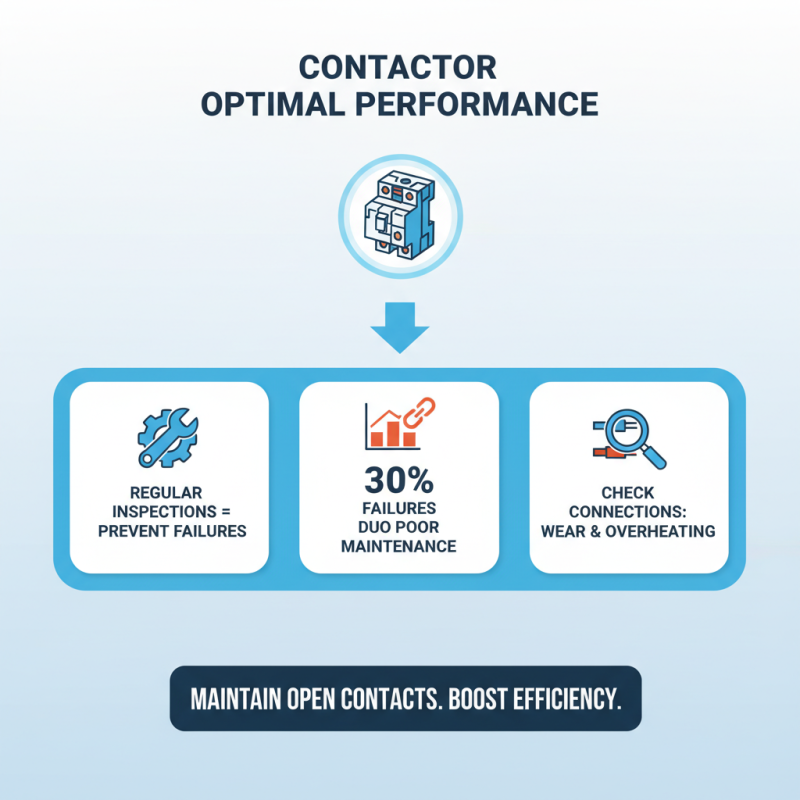

Maintaining open contactors is crucial for their optimal performance. Regular inspections can prevent unexpected failures. A report from the Electrical Engineering Association indicates that 30% of failures stem from inadequate maintenance. Therefore, check connections frequently. Look for signs of wear or overheating. These issues can drastically reduce efficiency.

Tips: Keep the contactor clean. Dust build-up can lead to overheating. Use a soft brush or compressed air. Furthermore, verify that your contactor is rated for the current it's handling. Under-rated contactors fail more quickly. A study reveals that using appropriately rated components increases lifespan by 40%.

Another aspect of maintenance involves regular testing. Conducting tests allows you to catch problems early. Monitoring voltage and amperage reduces risks. A small issue can escalate quickly. Yet, many users overlook this. Addressing problems promptly enhances reliability. Remember that a little attention goes a long way in prolonging the life of your contactors.